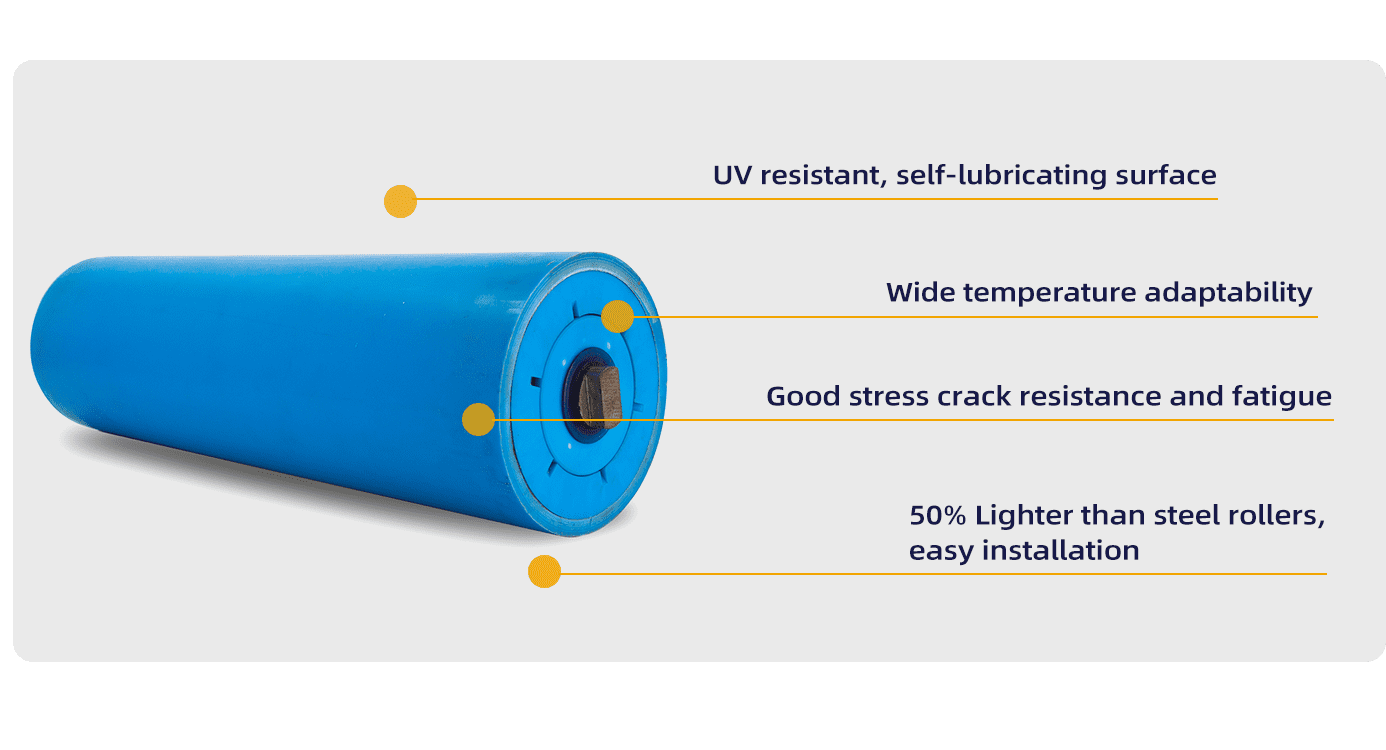

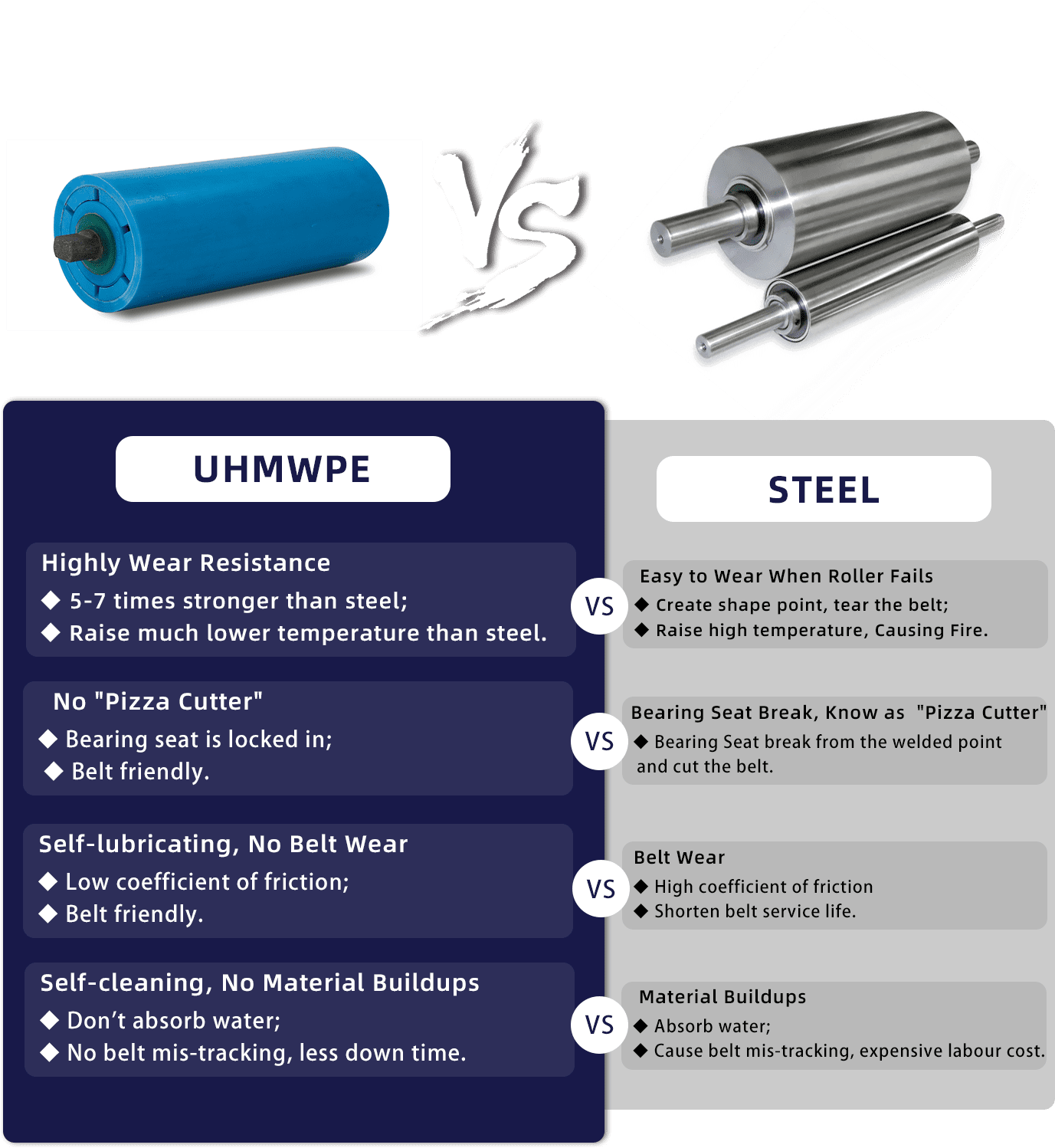

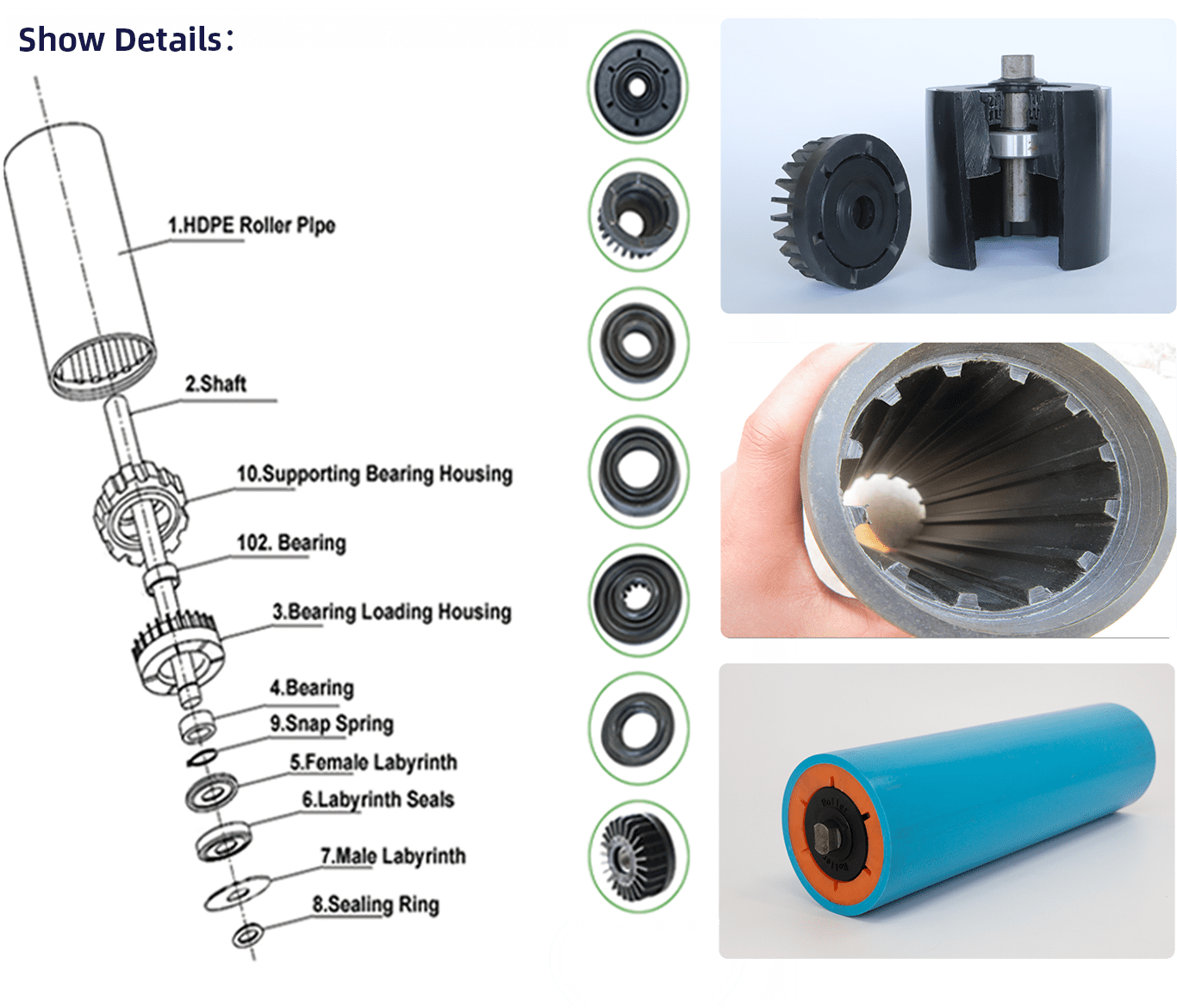

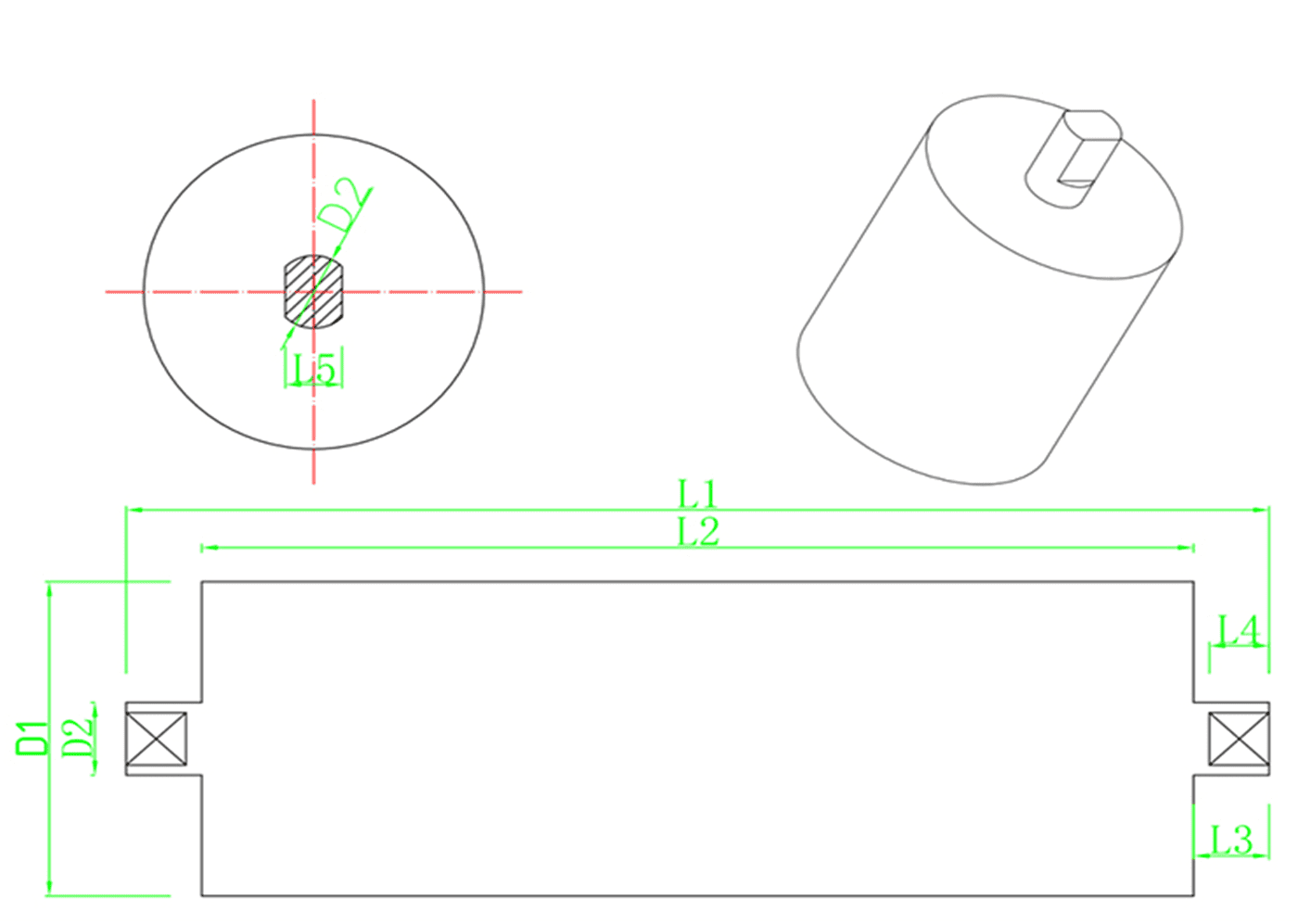

UHMWPE conveyor belt roller

UHMWPE conveyor belt roller has a novel structure, reliability seal, and advanced material selection. Rollers and housing are made of ultra-High Molecular Weight Polyethylene (UHMWPE) which has anti-friction self-lubrication, impact resistance, anti-adhesion, and anti-corrosion, resistant to aging, and other characteristics.

Get Price

Chat Now

Share With: